Stock Material

Fabrication

With a 5 Ton ProServ Overhead Crane, Branch Ironworks is capable of moving major steel through our shop for your fabrication needs.

Anchor Bolts

From the start of each project, you are going to want a way for your columns to stand up. We can take care of that. We supply Anchor Bolts and Embeds for all projects. We supply both Straight & Hook Style Anchor Bolts. Solid Rod is used, cut down to length and then threaded for nuts. We also Tack Weld the nuts onto the bottom of Anchor Bolts as well.

Embedded Items

If Anchor Bolts are not used or the job requires steel to be attached to concrete, we supply embeds. All of our embedded items come fully welded out with Nelson Studs. We offer all kinds of embeds, from plate embeds, to welding studs onto I-Beams for heavy duty applications.

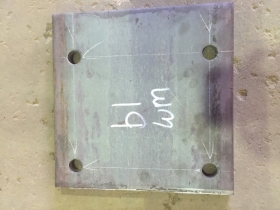

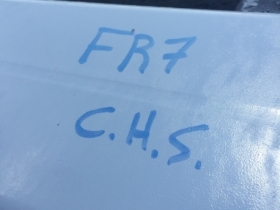

Parts Fabrication

All of our parts are made with care and pride, so that our fabrication process does not lose any valuable time. Our fabricators layout each piece, one by one, with all the correct markings for punching/notching. Each part is marked clearly with a paint marker, so that each fabricator has the correct part for assembly. If you require plate that has a certain bend or skew, no problem. We can get that taken care of for you. We use A Spartan Ironworker 110 to fabricate most of our parts. It shear up to 12” wide Flat Bar, Solid round and square bar & Angle. Along with shearing, it can also notch material for many different applications, as well as punch holes or slots for bolted attachments. We use Oxygen/Acetylene torches for most of our cutting needs. For our bigger materials, such as Tube Steel and Wide Flange Beams, we use a Jet Semi-Automatic Bandsaw HBS-1321W. It is capable of cutting material up to 2 feet wide and 60’ long. It cuts with excellent precision and quality. It completely illuminates the need for clean up with a grinder or other means. This allows the fabrication process to cut corners in time, literally.

Parts Assembly

Each fabricator has their own “Jig” or work station. Each fabricator handles their own parts and major pieces in the fabrication process. After the parts have been fabricated, they then make their way to the jigs for assembly. After each Major part has been cut, either using the Jet Band Saw or our Cutting Torches, they too make their way to the jigs. Each fabricator takes their respective drawings and begin to “Fit” or assemble each major piece. They use the layouts on the parts to fit onto each major piece. Once the part is in place, a Tack Weld is placed to hold the part onto the major piece. After all the parts are tack welded onto the major piece, each fabricator checks the major piece to ensure proper placement. They then begin to weld out the entire piece, applying the respective weld to each part, as called out on the drawings. Sometimes, major pieces call out for holes that need to be drilled. No problem. We use our Fien Short Slugger Mag Drills to take care of this. They take down fab time and produce 100% accurate holes. When fabricating columns, sometimes they require plates that are assembled through the actual tube steel. This is called a Through Plate. Our fabricators will cut slots into the tube steel in order for each plate to pass through the tube. Once the plate is through and properly laid out, the fabricator will then weld out all sides for proper fitment.

Misc. Steel

Along with all of the Structural Steel that we fabricate, we also handle most of the Miscellaneous Steel on each project. This can be handrails (1 Line, 2 Line, Multi Line & Specialty rails) stairs, canopy/awning frames, RTU frames for HVAC, roof access ladders, cages for ladders, bollards and dumpster gates.

Handrails

All of our handrails are fabricated to ADA Specifications. Our Handrail specialist in the shop, Erica, is capable of turning a nightmare into a dream. She can take handrails that have been poorly fabricated or deteriorated over time and turn them into an absolute masterpiece. Wether it needs a quick fix or it needs to be completely re-fabricated, Erica can take care of it. If our project calls for steel handrails, you can bet that you will see Erica’s artwork there. We use a Dake Cold Saw to make our cuts for handrails. It uses a cutting fluid with a steel saw blade, to produce the most accurate cut possible, at any angle, all while keeping the material cold to the touch. With the Dake Cold Saw, Erica is capable of creating magnificent handrails, without sacrificing time. Not only can we provide clean and accurate cuts for handrail assembly, we also have the ability to apply many different types of notches to handrails. When two pieces of pipe meet up with each other, one has to cradle to other one. That is where our Pipe Notcher comes in. Capable of notching up to 3” pipe, it helps create a clean and professional look for all your handrail needs. With the quality of cut added to the quality of weld Erica puts down, each and every handrails comes out ready to install, with minimal to no clean up. Branch Ironworks takes absolute pride in the work that we produce, no matter if it is seen by the public eye or not. That same pride is seen throughout each of our fabricators.

Dumpster Gates

As with most projects, Dumpster Gates & Enclosures are common. We can provide your project with all the steel needs, just for that. We can provide you with the embedded items such as the Dumpster Posts & Pipe Bollards. The Dumpster Gates, if made from steel, are also provided by us. Generally, we wait for the Dumpster Posts to be set into the concrete, then get our dimensions for the gates and fabricate them to fit, in our shop.

RTU Frames

For the HVAC units, we provide many different variations of RTU framing. Most of the time we provide angle iron, with notches for proper placement in the field. As oppose to the fabrication of main pieces and other misc. steel, we only cut to length the Roof Top Units, so that the Erectors can fit them properly in the field. With welding RTU frames prior to erection, you risk the chance of the material not fitting properly and having to re-fabriacte the parts, which costs valuable time and money.

Stairs

All of our stairs are fabricated in shop. No matter how big or small, we can get them done right the first time. With over 40 years of experience, Eddy Branch provides the most accurate stair layouts for our fabricators to use. Each stair is fabricated using Field Verified dimensions, so that the field placement has no issues. We also provide stair cases with handrails already attached.

Ladders

Need to get to the top? We can help. We provide Roof Access Ladders on most all of our projects. Need a cage? We can help! We can provide your ladders with the proper safety cage, wether it calls for a security door or just a standard cage. Along with the ladder, we also provide framing around the Roof Hatch. We do not offer any Roof Hatches or BILCO products.

Finishing

Once our material has been properly assembled and welded up 100% or to specifications, it then moves to our paint booth. All major pieces are marked with a Final Piece mark with a Bleed Thru Marker. Each marker is made for Oil based paints and literally bleeds through the primer during the drying process, to show the erectors what piece it is. Each mark shows through the primer in a vibrant Red or Blue color. Each major piece is marked with it’s respective directional mark for erection as well. Our fabricator’s goal is to provide the erectors with 100% mistake free steel, that can be erected without any flaws. We mark all of our steel with only the marks our erectors need for erecting purposes.

We prime all of our steel with a standard Grey Shop Coat provided by Horn Paint out of Fort Worth, Texas. Paint is great for protection against the elements, however, sometimes you need a stronger solution.

Galvanizing applies a layer of Zinc, through a process called “Hot Dipping”, to your material that protects it from the elements for an extremely long time. If your material calls to be Galvanized, we can get that done for you as well. With 3 local galvanizing plants, we have options available to meet your needs. Prior to sending the material to the galvanizer, we make sure each piece is properly marked with it’s respective piece marks. In order not to lose the mark during the galvanizing process, we weld each piece mark onto each piece. We do not obstruct any parts or weld with our piece marks. Along with proper piece marks, we also put holes in hollow material to allow proper drainage when the material is dipped into the Zinc for galvanizing. If holes are not put into the hollow materials, it can cause the material to explode inside of the Vats used for galvanizing, causing major injury or death. Proper set up for the galvanizer is extremely important. Sometimes, galvanizing doesn’t do justice because of the one main color it comes in, silver. It can be painted over and a lot of the times, it is.

However, if you would like a custom look, Powder Coating is also another option. Powder Coating is typically applied electrostatic-ally and then is cured under heat to allow it to flow smoothly and form a protective layer, also known as “skin”. The powder can either be a thermoplastic or a thermoset polymer. Powder coating is typically used to create a hard finish that is tougher than conventional paint.

When your material is ready to be shipped to the job site, we make sure it arrives just as it left our yard. For anchor bolts and embedded items, we can place most items onto a pallet and wrap with shrink wrap. Each pallet is secured and allows no room for material to come lose during transportation. If the material is too big for pallets, our fabricators make sure to properly group the material together for banding purposes. Each group of material is banded with 3/4” steel scraping and banded together with steel clasps for a secure load during transportation. Each pallet or banded group is properly marked for shipping purposes. Along with your material, you will receive a detailed shipping ticket, showing all of the material shipped on that truck/trailer. Once checked and signed for, our erectors unload the material and begin the erection process.